绞盘使用指南:关于各类数值的计算

There is a large amount of information that could be needed in order to properly size a winch or hoist. On this page we will go thru each item of information and you can decide if it is needed for your application:

1: Do I need a Winch or Hoist

A winch is for pulling along the ground (up to a 30 degree incline).

A hoist is for pulling at incline from 30 degrees to loads that are free suspended and vertical.

There are some situations above the 30 degree rule where a winch can still be used. An example is if there is some other type mechanism that will hold the load in the case of failure of the winch. Another example is if your load is dropping into the water.

Because a hoist is lifting objects vertically and possibly above a persons head, an extra brake mechanism is needed. Many governing bodies, such as OSHA in the United States, require extra safety features for hoists. Be sure you check with the governing body for your application to be sure you have what you need.

2. What will power the winch? (manual / air / electric / hydraulic)

Manual - Hand Crank or Hand Wheel

A hand wheel is preferred over a hand crank in the case of winches with higher load and / or winches that will be used often. A hand wheel will make lifting the load easier for the operator. Be sure to see what the gear ratio of the winch you purchase is. Also, check the amount of force needed to turn the crank of the winch or hoist to the pull the load you need.

Pneumatic - Air Powered

Pneumatic motors are expensive and very loud as compared to hydraulic. However, air compressors are much more available as compared to hydraulic power packs. Air winches are explosion proof and are suitable for situations where this feature is needed. Should you decide upon a pneumatic winch or hoist be sure to know what pressure and volume of air is required in order to power the unit you need. If you do not supply the winch or hoist with the pressure (pounds per square inch) and amount (cubic feet per minute) of air needed, it will still operate, but at reduced line pull and speed.

Electric Powered

Electric power and electric motors are readily available and not costly. This makes them suitable for a majority of applications. In additon, you dont need an air compressor or hydraulic power pack. The downsides are that faster speed and higher line pull units require larger power supply (higher voltages and 3 phase) quite quickly. Also electric winches and hoists are not explosion proof unless costly explosion proof motors and control boxes are included. When requesting a quote for an electric winch or hoist you must specify the hertz (50 or 60 Hz), volts (220, 400, 440 etc) and phase (1 or 3).

Hydraulic Powered

If you have a source for hydraulic power, then hydraulic winches are cost effective and can reach very high line pull and line speed at reasonable cost. Should you decide upon a hydraulic winch or hoist be sure to know what pressure and volume of oil is required in order to power the unit you need. If you do not supply the winch or hoist with the pressure and amount of air needed, it will still operate, but at reduced line pull and speed.

3. Line pull needed (how heavy is maximum load)?**

You must determine how much pull (pounds or KG) that the winch or hoist will need to overcome. This may not always be easy. If you are pulling a boat and trailer that has a weight of 5 tons up a ramp that is 30% incline then what capacity winch do you need? Certainly it will be less than 5 tons. See section 12 below to learn how to compute.

Another consideration is if you should multi part the line. "Multi part" means using a pulley system. As an example if you 2 part the line then you will double the winch line pull and 1/2 the winches line speed. A 2 part line runs from the winch drum, thru a pulley at the load and then back to the winch (or near the winch) and secured. The more pulley used the greater the line pull of the winch but the slower it will operate.

4. Line speed needed (how fast does the line need to pay in and out)?**

You must determine how fast (the speed of the line or line speed) that the load will be pulled (feet or meters per minute). You can do so by taking the distance that you need to move the load and dividing by the speed of the winch. As an example: 100 feet divided by 10 feet per minute = 10 minutes. Is the time you come up with fast enough? Or can you reduce speed and use a winch that is less costly?

5. How far do you need to pull the load?**

You must determine how far the load you are pulling or lifting needs to be moved. (feet or meters)

6. What size line (inches or mm) is required for the winch or hoist?**

The agency governing the use of your winch may have a particular safety factor required. If so, state what that safety factor is and Pacific Marine & Industrial can size the wire to meet it. If not, then we can recommend a wire size given common safety factors. Typical safety factors are 4 to 1 and 5 to 1. As an example, if a wire has a 92 ton breaking load and you want to use a 5:1 safety factor, then the winch you use should have no greater line pull than 18.4 tons.

** A few comments about items 3 to 6 above:

A winch drum is a cylinder. When wire is wrapped around that cylinder in many layers (full drum) the winch will operate at higher line speed and lower line pull. When the winch is at bare drum (no wire on the drum) the winch will operate at slower line speed and higher line pull. All of the items 3, 4, 5 and 6 as well as the drum size and width are required in order to be sure that the winch or hoist will not go under the desired line pull and line speed for a given application.

7. Is a hook or eye needed at the end of the wire? Do you want the wire included with the winch?

State what is needed for your application.

8. What type of controls are needed for your application?

Control Box: Electric Winches and Hoists

Control Pendant: Electric, Hydraulic or Pneumatic

Winch Mounted Controls: Hydraulic or Pneumatic Winches and Hoists

Variable Speed Controls or Start / Stop / Reverse: Electric Only

Foot Switch: Electric, Hydraulic or Pneumatic

Hydraulic and Pneumatic winches have a valve to control the flow of air or hydraulic oil to the winch or hoist. These valves allow variable speed and reverse direction automatically. They can be mounted on the winch or they can be in a hand held pendent or foot switch.

Electric winches have much less costly controls that are constant speed and allow the winch to start / stop / reverse. If you would like variable speed on an electric winch a more costly variable frequency drive must be purchased as part of the control package.

9. Are their any special requirements?

Split drum: some winches have two wires coming off the drum and need a split drum. A split drum is a flange placed vertically that will separate the 2 wires and not allow them to tangle.

Grooved drum: putting a groove in the drum helps the 1st layer of wire wrap onto the drum correctly.

Level wind: a level wind helps all layers of wire wrap onto the drum correctly.

Epoxy (marine) top coat: some applications require an epoxy top coat

Explosion proof: oil and other industry require explosion proof winches and hoists

10. What is the duty cycle? (how many minutes per hour will the unit be used or is there going to be continuous use?

Most industrial winches are designed for constant duty and can be operated 100% of the time. Lighter duty winches and hoists have reduced duty cycles. In some cases as few as 15 minutes per hour or 25%. Be sure you specify what you duty cycle is and purchase a winch or hoist that will meet it.

11. Fleet Angle

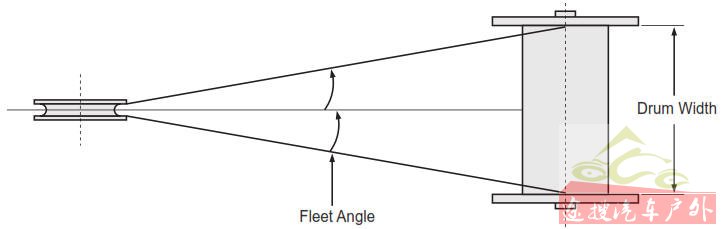

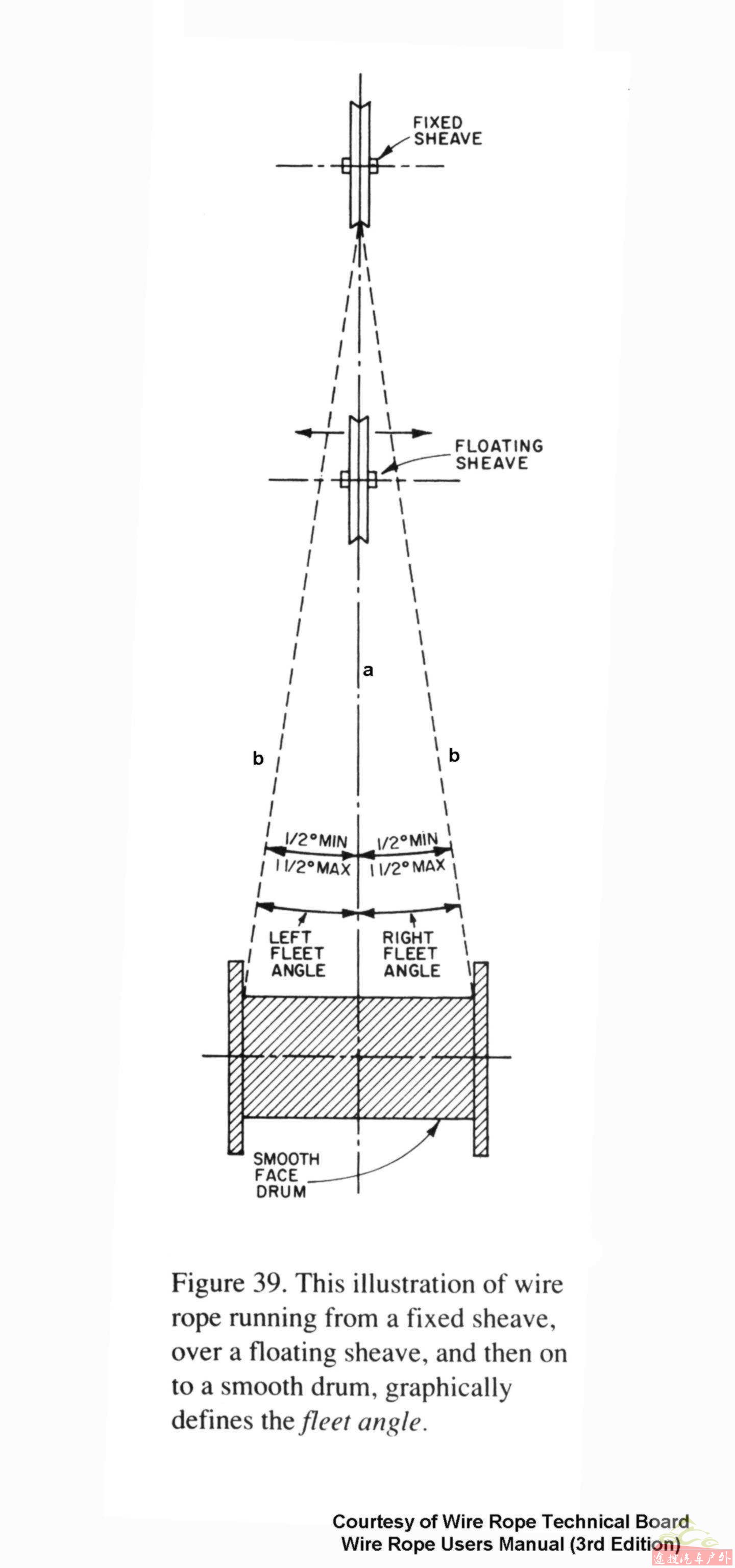

fleet angle descripton: winches and hoists

To prevent excessive wire rope wear and damage and ensure the safety of operators, a location that permits proper fleet angle is necessary to let the wire rope spool uniformly onto the drum. Proper fleet angle is between 1/2o and 1-1/2o measured as illustrated in the example above. As a general "rule of thumb", the absolute minimum distance from the winch to a fixed sheave should be equal in feet to the drum length in inches. For example, a 12" wide drum requires a fixed sheave at least 12' feet away for proper spooling.

12. Computing Line Pull When Load Travels Up An Incline

Required Line Pull = W(Gr+Cf)

W= Weight

Gr = Grade Resistance

Cf = Coefficient of Friction

As an example: If we are pulling a steel bin on wheels up a 30% cement grade with total weight of 5 tons what line pull winch do we need?

Line Pull = 5 Tons x (.288 + .2 to .5) = 2.44 to 3.94 tons.

See below tables for values:

|

Coefficient of Friction | |

|

.40-.60 |

Steel on Steel |

|

.40-.60 |

Wood on Concrete |

|

.30-.70 |

Steel on Concrete |

|

.02-.05 |

Load on Wheels |

|

.05-.10 |

Load on Rollers |

|

Grade Resistance | |

|

| |

|

% Grade |

GR |

|

5 |

0.05 |

|

10 |

0.1 |

|

20 |

0.196 |

|

30 |

0.288 |

|

40 |

0.372 |

|

50 |

0.448 |

|

60 |

0.513 |

|

70 |

0.573 |

|

80 |

0.624 |

|

90 |

0.669 |

|

100 |

0.701 |

|

200 |

0.896 |

|

400 |

0.97 |

|

Vertical |

1 |