如何操作手动绞盘(英文)

Above you see the genuine TIRFOR, called also an GRIPHOIST in the US and GREIFZUG in Germany. The one above dates from the 80's while the larger below was probably produced in the 60's. But they don't wear out.

This is an assortment of what you need. The Tirfor is shown in 2 sizes. The small one is rated at 800 kg, the larger on below lifts 1500 kg. Safety factor is 5. The 800 kg version is, in my personal experience, suitable for all standard tasks. You need the larger (and much heavier) version only if you are really hopelessly stuck. The large one is rated at 1500 kg which is, by all standards of winch manufacturers, absolutely not sufficient. Well I once pulled my International Scout (2.5tons) through a bottomless rut for 3x 50 metres with this one. And it had really all 4 wheels in the air. BTW, the hook on the larger one is marked 3500 kg, a much better estimation of it's pulling power I think.

If you work with a Tirfor you MUST ABSOLUTELY use the genuine cable. A standard cable is soft which means you can squeeze it. So it can slip out of the jaws inside the Tirfor - with lethal outcomes. If you use the right cable it will break before it can slip out of the jaws. And a cable never breaks without warnings. It will make all sorts of sounds and then start breaking slowly.

The extendable handle is the genuine one for the large model but inserting a short length of 3/4" water pipe makes it an ideal fit for the small model.

The pulley on the other side is a bit small. The manufacturer of the cable states a minimum diameter of 20x the cable size for safety reasons.

Heavy leather gloves are always a must when handling steel cables.

Next you need an nice assortment of heavy clamps. Only use screw-in types, they are much more resistant to distortion. In any case you must tighten the clamp, then loose it up for 90°. Else it will bite itself so hard under load that you need pliers to open it. In many cases you will also need one or two chains as well as a tree strap or a standard strap.

Start with unreeling the cable. It's easiest when one holds the reel loosely while the other pulls on the cable.

One of the not-so-great features of the Tirfor is that you must unreel ALL the cable as you must insert one end into the machine.

Now lay the strap around a suitable tree as low as possible. You may never, NEVER use a cable or chain for this. If the skin of the tree is damaged deeper than an inch all around the tree will die. A strap spreads the load so much it will not hurt the tree.

Now tie the 2 ends of the strap together with a large clamp and hang the Tirfor also in this clamp. You should use a clamp to prevent the strap from damage as the cable comes out very close to the ends. The clamp deflects it.

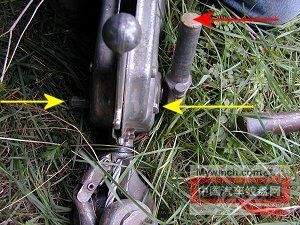

In order to feed the cable you must disengage the clutch. For doing this you must pull the clutch lever (below, red arrow) up while pushing the safety lock (yellow arrow) to the lever side. If it's hard get out your can of WD40 and spray INSIDE the Tirfor. This construction wants an well oiled interior and don't worry, it will not make the cable slip.

Then you can easily feed the cable through (above right).

On a standard 90/110/130 there are surprisingly few solid anchoring points up front. Either you fitted Jates-rings (recommended) or you must use the genuine tow points. Those are however not designed for such a manoeuvre, being made of stamped steel and hold by a single bolt. They are intended for towing light loads on tarmac.

One possibility is however shown above. First you insert an 19 or 23 mm C-clamp on BOTH sides as this halves the load on each tow point(above left). Then you pull an heavy chain through them (the chain is too large to fit directly) and clamp the chain correctly onto itself (above right).

It's important that the chain makes as small an angle as possible as the load increases otherwise. But you still have a safety problem inherent to the working of the Tirfor. Unlike the electrical or mechanical winch you must stand very close to the cable under load. A snapping anchoring point may kill or severely injure you. So I put an small clamp over the cable near the dangerous end. To this I connect an spare strap.

The idea behind this is to catch the force if something breaks and the cable snatches back.

The other end of the strap is loosely wound around some part of the car. Here I used the bullbar but you can also wind it around the spare tire- no importance. It's just to catch the kinetic energy. This works a lot better than putting carpets on the line or opening the hood.

Now to the REAL work as Annette shows here. The cable is pulled on both moves of the lever. Every full move pulls the line between 5 and 7 cm (2 and 3 inches). This sounds quickly but in real life it's a pain in the ass. 2 people working together makes the work much easier. Notice how the large clamp guides the steel cable away from the nylon strap.

After having got the vehicle unstuck move the long actuating lever to the other stub (above left). This pulls the cable backwards. After taking off the load you can disengage the clutch by lifting and pushing on the safety (yellow arrows above right). The reserve of overload sheer pins is inside the handle under the plastic cover (red arrow),

After the work is done you must roll up the cable again. Those special cables just don't like being thrown in the back. If you get kinks in them it will be very hard to guide the cable through the Tirfor. So feed them on their reel correctly. Later you must clean and oil them.